Plastiki Pipe Extrusion

-

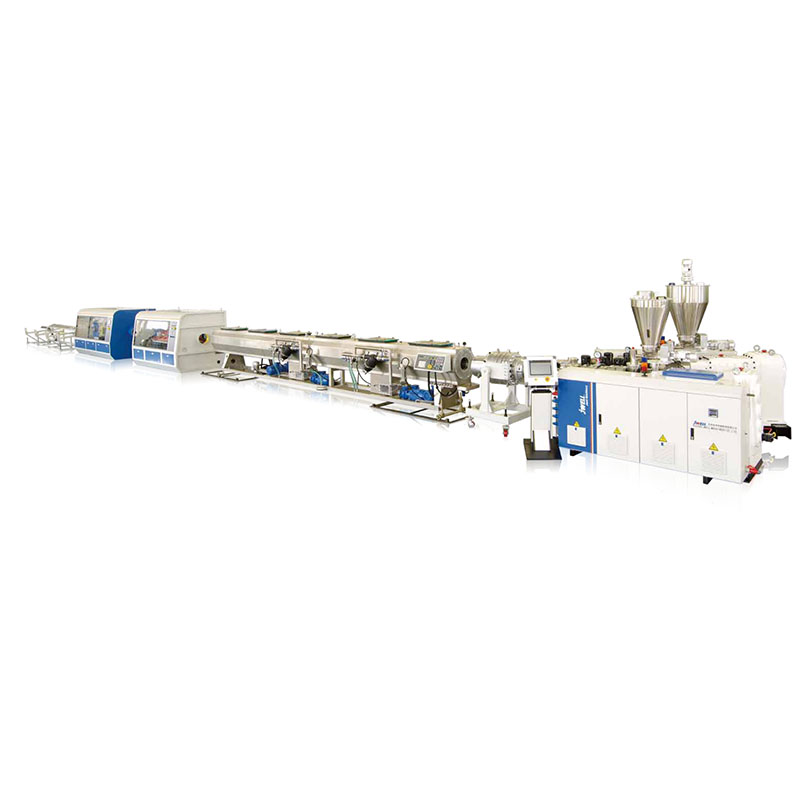

Mohala o moholo oa Diameter HDPE Pipe Extrusion Line

Tshebetso & Melemo: Extruder ke letoto la JWS-H Bokhoni bo phahameng, tlhahiso e phahameng ea sekoti se le seng sa extruder. Moralo o khethehileng oa sebopeho sa "screw barrel" o netefatsa ho ts'oana ho hoholo ha mocheso o tlase oa tharollo. E etselitsoe bakeng sa extrusion ea liphaephe tse bophara bo boholo, hlobo ea sebopeho sa kabo ea spiral e na le sistimi e pholileng ea ka hare ea pompo ea mold. E kopantsoe le thepa e khethehileng e tlaase, e ka hlahisa liphaephe tse nang le marako a mangata, a maholo a bophara. Hydraulic e bula le ho koala tanka ea li-vacuum ea mekhahlelo e 'meli, taolo e bohareng ea khomphutha le khokahanyo ea literekere tse ngata tsa li-crawler, mochini o sehang o se nang chip le likarolo tsohle, boemo bo phahameng ba boiketsetso. Terekere ea terata ea boikhethelo e ka etsa hore ts'ebetso ea pele ea tube e kholo e be bonolo haholoanyane.

-

Silicon Coating Pipe Extrusion Line

Thepa e tala ea silicon core tube substrate ke polyethylene e phahameng haholo, karolo e ka hare e sebelisa setlolo se tlase sa silika sa silika se tiileng. Ke ho hanyetsa kutu, lebota le ka hare le boreleli, phetisetso ea khase e fefolang khase, le litšenyehelo tse tlase tsa kaho. Ho ea ka litlhoko, boholo bo fapaneng le mebala ea li-tubes tse nyenyane li tsepamisitsoe ke casing e ka ntle. Lihlahisoa li sebelisoa ho optical cable communication network system bakeng sa freeway, terene joalo-joalo.

-

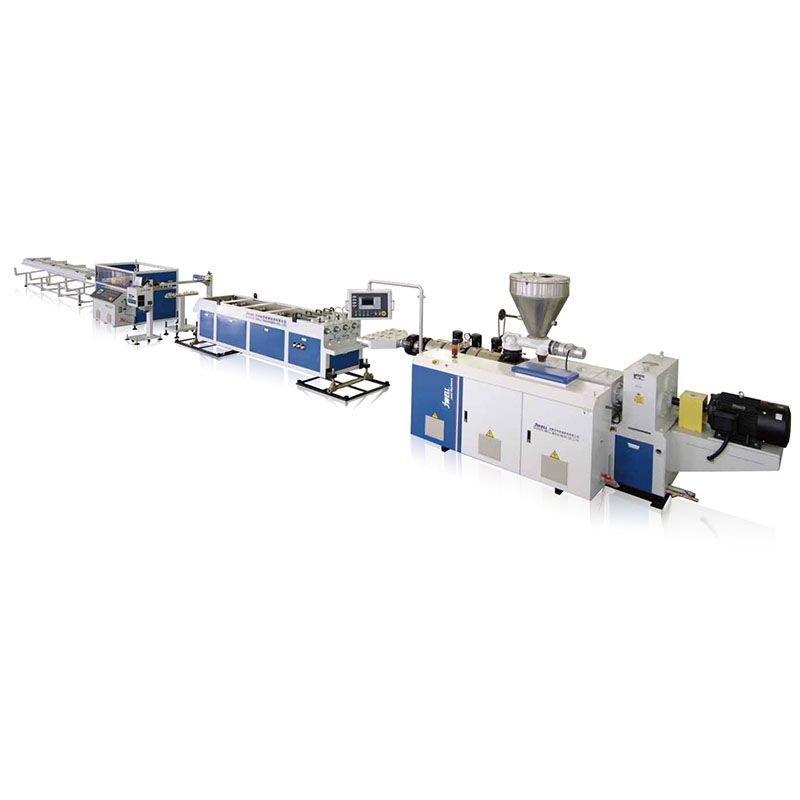

PVC-UH/UPVC/CPVC Pipe Extrusion Line

Mefuta e fapa-fapaneng ea litlhaloso le mehlala ea PVC twin-screw extruder e ka hlahisa liphaephe tsa bophara bo fapaneng le botenya bo fapaneng ba marako. Sebopeho se entsoeng ka ho khetheha sa screw se nang le polasetiki e ts'oanang le lihlahisoa tse phahameng. Mefuta ea Extrusion e entsoeng ka tšepe ea boleng bo phahameng ea alloy, channel ea ka hare ea chrome plating, phekolo ea polishing, ho apara le ho hanyetsa ho bola; ka letsoho le inehetseng le phahameng ka lebelo le phahameng, boleng ba phaephe bo botle. Sehahi se khethehileng bakeng sa pipe ea PVC se amohela mochine o pota-potileng oa ho koala, o sa hlokeng ho nkela thepa sebaka ka bophara bo fapaneng ba pipe. Ka sesebelisoa sa chamfering, ho itšeha, ho qhekella, ho bopa mohato o le mong. Ts'ehetsa mochini oa tšepe oa inthaneteng oa boikhethelo.

-

Three Layer PVC Pipe Co-extrusion line

Sebelisa tse peli kapa ho feta tsa SJZ letoto la conical twin screw extruder ho kenya ts'ebetsong phala ea PVC e kopantsoeng ka mekhahlelo e meraro. Lera la sandwich la phala ke lisebelisoa tse tala tsa PVC kapa PVC ea foam ea calcium e phahameng.

-

PVC Dual Pipe Extrusion Line

Ho tsamaellana le litlhoko tse fapaneng tsa bophara ba pipe le tlhahiso, ho na le mefuta e 'meli ea SJZ80 le SJZ65 e khethehileng ea mafahla-screw extruders khetho; phala e 'meli e shoa ka mokhoa o ts'oanang e aba lihlahisoa tsa thepa,' me lebelo la extrusion la pipe le potlakisa polasetiki. Lebokose le pholileng le sebetsang hantle ka makhetlo a mabeli a vacuum le ka laoloa ka thoko, 'me ts'ebetso ea tokiso e loketse ts'ebetsong ea tlhahiso. Mochini oa ho itšeha o se nang lerōle, taolo e ikemetseng ea seteishene sa habeli, lebelo le potlakileng, bolelele bo nepahetseng ba ho itšeha. Li-clamp tse potolohang ka moea li felisa tlhoko ea ho fetola li-clamps. Ka sesebelisoa sa chamfering boikhethelo.

-

PVC Four Pipe Extrusion Line

Litšobotsi tsa ts'ebetso: Mofuta oa morao-rao oa mela e mene ea tlhahiso ea lihlahla tsa motlakase oa PVC o amohela li-twin-screw extruder tse nang le tlhahiso e phahameng le ts'ebetso e ntle ea polasetiki, 'me e na le hlobo e ntlafalitsoeng bakeng sa moralo oa tsela ea phallo. Liphaephe tse 'nè li tsoa ka ho lekana 'me lebelo la extrusion le potlakile. Litanka tse 'ne tsa ho futhumatsa li-vacuum li ka laoloa le ho lokisoa ka bonngoe ntle le ho ama tse ling ts'ebetsong ea tlhahiso.

-

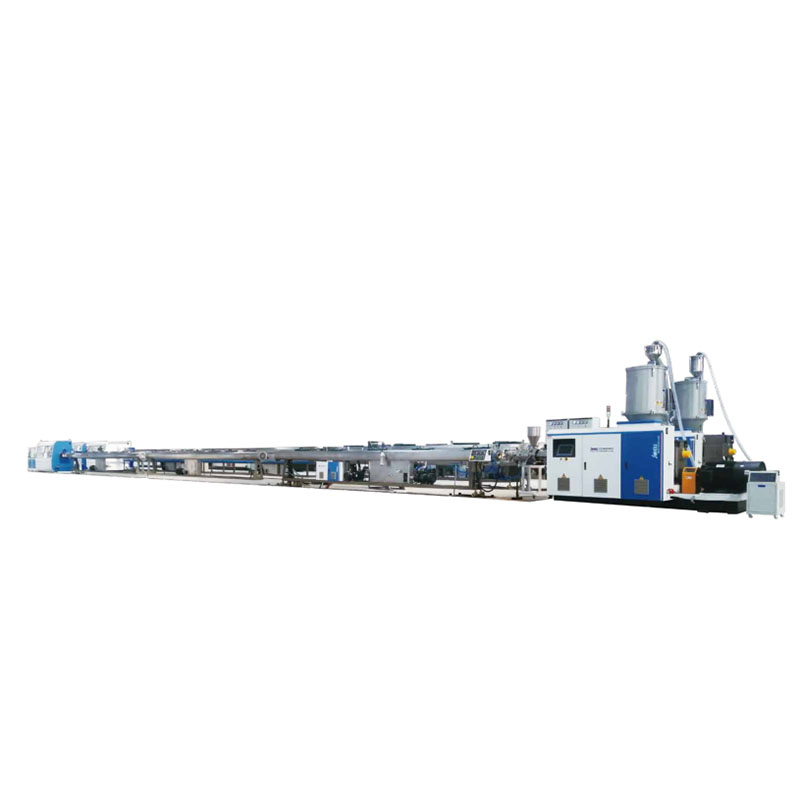

HDPE Pipe Extrusion Line ea lebelo le phahameng e bolokang Matla

Pipe ea HDPE ke mofuta oa phala ea polasetiki e tenyetsehang e sebelisetsoang phetisetso ea mokelikeli le khase, 'me hangata e sebelisoa ho nkela konkreite e tsofetseng sebaka kapa liphaephe tsa tšepe tse kholo. E entsoe ho tloha thermoplastic HDPE (polyethylene e phahameng-e phahameng), boemo ba eona bo phahameng ba ho se hlolehe le tlamo e matla ea limolek'hule e etsa hore e tšoanelehe bakeng sa liphaephe tse phahameng tsa khatello. Peipi ea HDPE e sebelisoa lefatšeng ka bophara bakeng sa lits'ebetso tse joalo ka likhoele tsa metsi, likhoele tsa khase, likhoele tsa likhoerekhoere, likhoele tsa ho fetisoa ha seretse, nosetso ea mahaeng, likhoele tsa phepelo ea litsamaiso tsa mollo, kotopo ea motlakase le likhokahano, le lipeipi tsa metsi a sefefo le tsa drainage.

-

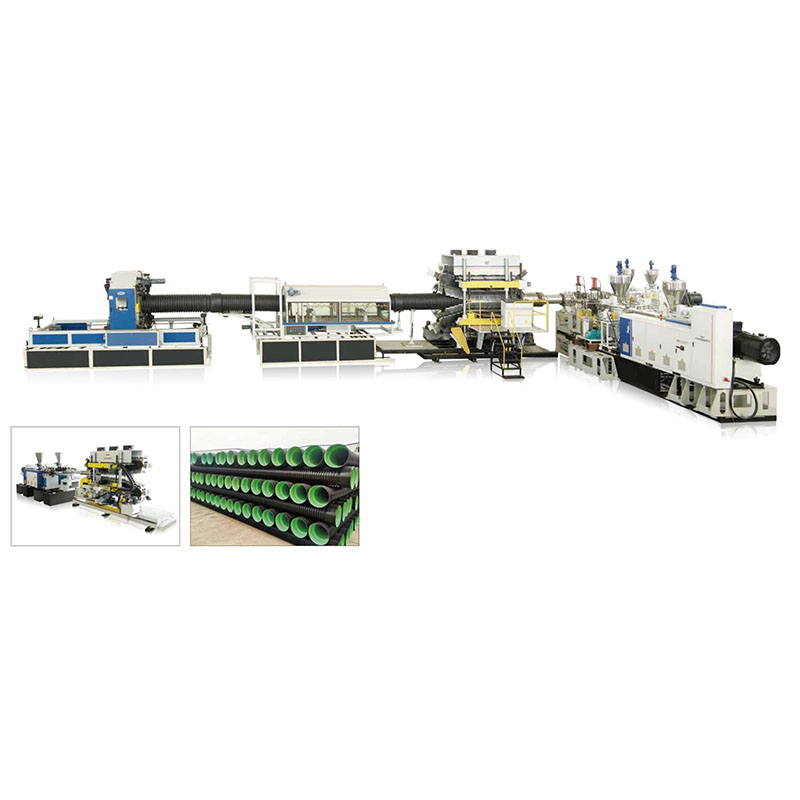

High-speed Single Screw HDPE/PP DWC Pipe Extrusion Line

Mohala oa peipi ea masenke ke moloko oa boraro oa sehlahisoa se ntlafalitsoeng sa Suzhou Jwell. Sehlahisoa sa extruder le lebelo la tlhahiso ea phala li eketsehile haholo ka 20-40% ha li bapisoa le sehlahisoa se fetileng. Ho betsa ka Marang-rang ho ka finyelloa ho netefatsa ts'ebetso ea lihlahisoa tsa liphaephe tse entsoeng ka masenke. E amohela tsamaiso ea Siemens HMI.

-

Parallel/Conical Twin Screw HDPE/PP/PVC DWC Pipe Extrusion Line

Suzhou Jwell o hlahisitse theknoloji e tsoetseng pele ea Europe le mohala o sa tsoa ntlafatsoa oa parallel-parallel screw extruder HDPE/PP DWC.

-

Multi-layer HDPE Pipe Co-extrusion Line

Ho ea ka litlhoko tse khethehileng tsa basebelisi, re ka fana ka 2-layer / 3-layer / 5-layer le multilayer tiileng lerako pipe line. Li-extruder tse ngata li ka kopanngoa, 'me tsamaiso ea ho laola boima ba limithara tse ngata e ka khethoa. e ka ba bohareng ba taolo ho PLC e kholo ho fihlela extrusion e nepahetseng le e ngata ea extruder ka 'ngoe. Ho ea ka hlobo ea li-spiral tse ngata tse entsoeng ka mekhahlelo e fapaneng le karo-karolelano ea botenya, kabo ea phallo ea sekoahelo sa hlobo.liteishene lia utloahala ho etsa bonnete ba hore botenya ba lera la tube bo lekana le phello ea polasetiki ea lera ka leng e betere.

-

Metsi a Hatelitsoeng a Pholisa HDPE/PP/PVC DWC Pipe Extrusion Line

HDPE Corrugated Pipes e sebelisoa mererong ea likhoerekhoere lipalangoang tsa litšila tsa indasteri pompong ea metsi a sefefo le ho tsamaisa metsi a likhoerekhoere.

-

HDPE Heat Insulation Pipe Extrusion Line

Pipe ea ho kenya letsoho ea PE e boetse e bitsoa PE ea tšireletso ea kantle, phala ea baki, phala ea matsoho. Pipe e kenang ka kotloloho ea polyurethane e entsoe ka phala ea insulation ea HDPE joalo ka lera le kantle la ts'ireletso, foam e bohareng e tlatsitsoeng ke polyurethane e thata e sebelisoa e le lera la thepa e kenang, 'me lera le kahare ke phala ea tšepe. Pipe ea polyurethane e patiloeng ka kotloloho e na le thepa e ntle ea mochini le ts'ebetso ea ho kenya mocheso. Tlas'a maemo a tloaelehileng, e khona ho mamella mocheso o phahameng oa 120-180 ° C, 'me e loketse merero e fapaneng ea metsi a batang le a chesang a phahameng le a tlaase a mocheso oa lipeipi.